The old days of manual processes at storage terminals and loading terminals are fading fast. Modern facilities across North America are integrating more and more automation into their processes, and older control systems are being strained to the limit trying to keep up.

Modern storage and loading facilities demand control systems that ensure safe, efficient, and compliant operations. For facility managers and petrochemical executives planning new installations or upgrades, understand that designing control panels represents a critical investment that directly impacts operational safety, regulatory compliance, and long-term facility performance. Let’s talk about why that is:

The Critical Role of Control Panels in Terminal Operations

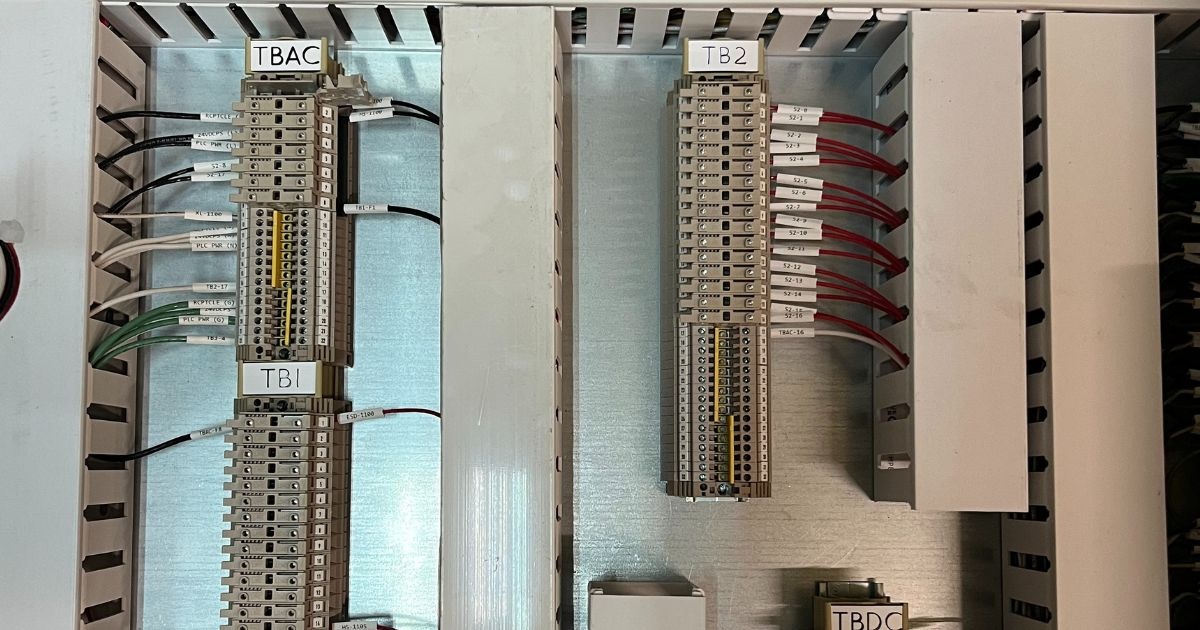

Control panels serve as the nerve center for storage terminal and loading terminal operations, managing everything from product flow rates and tank levels to safety shutdown systems and environmental monitoring. Ideally, these systems integrate seamlessly with existing infrastructure while providing operators with intuitive interfaces that support rapid decision-making during routine operations and emergency situations.

Aura Engineering understands that designing control panels for petrochemical facilities requires deep knowledge of industry regulations, operational workflows, and safety protocols. Our experience with diverse terminal configurations enables us to create control solutions that enhance operational efficiency while maintaining the highest safety standards.

Essential Components of Terminal Control Panel Design

The team of engineers here at Aura takes a lot of pride in having created modern, efficient control panels for facilities across the U.S. We know that effective control panel design begins with a comprehensive analysis of facility operations and regulatory requirements. Storage terminals typically require monitoring and control capabilities for multiple tank farms, vapor recovery systems, and product transfer operations. Each of these systems demands specific instrumentation, alarm capabilities, and operator interfaces that must be integrated into a cohesive control architecture.

Loading terminal applications present additional complexity, as control panels must coordinate truck loading operations, rail car loading sequences, and marine vessel loading procedures. These operations require precise flow control, overfill protection, and documentation systems that ensure accurate product custody transfer and regulatory compliance.

Modern control panel designs incorporate programmable logic controllers (PLCs) that provide the flexibility and reliability required for continuous terminal operations. These systems enable remote monitoring capabilities, automated safety responses, and data logging functions that support both operational efficiency and regulatory reporting requirements.

Safety Integration in Control Panel Systems

Safety represents our paramount concern in designing control panels for petrochemical storage and loading facilities. Emergency shutdown (ESD) systems must always be integrated seamlessly into control panel designs, providing operators with immediate response capabilities during emergency situations. These systems typically include manual shutdown capabilities, automatic responses to dangerous conditions, and clear visual and audible alarm systems.

Aura Engineering’s approach to control panel design emphasizes redundancy in critical safety functions, ensuring that single-point failures cannot compromise facility safety. Our designs incorporate industry-standard safety instrumented systems (SIS) that meet or exceed API and IEC safety standards for petrochemical facilities.

Fire and gas detection integration represents another critical aspect of control panel design for storage terminals and loading terminals. These systems must provide early warning of potentially dangerous conditions while integrating with facility fire suppression and evacuation systems.

Regulatory Compliance and Documentation Requirements

Designing control panels for petrochemical terminals requires thorough understanding of applicable regulations, including EPA requirements for vapor control, OSHA standards for workplace safety, and DOT regulations for product transfer operations. Control panel designs must incorporate the monitoring and documentation capabilities necessary to demonstrate ongoing compliance with these requirements.

Aura Engineering maintains current knowledge of evolving regulatory requirements and incorporates compliance features into every control panel design. (We helped write some of those requirements!) Our documentation packages include detailed operation and maintenance manuals, calibration procedures, and compliance checklists that support facility certification and ongoing regulatory inspections.

Technology Integration and Future-Proofing

Automation technology evolves rapidly, and control panels must be able to evolve with them. A good control panel designer is an expert in integration with enterprise systems. SCADA integration capabilities enable remote monitoring and control functions that support centralized operations management across multiple facilities. These systems also provide the data connectivity required for predictive maintenance programs and operational optimization initiatives.

Cybersecurity considerations have become increasingly important in designing control panels for critical infrastructure facilities. Aura Engineering incorporates industry-standard cybersecurity measures into our control panel designs, including network segmentation, access control systems, and secure communication protocols.

Maintenance and Lifecycle Considerations

Effective control panel design considers long-term maintenance requirements and component lifecycle management. Standardization of control components simplifies spare parts inventory and reduces maintenance training requirements. Accessible component layout and clear documentation support efficient maintenance operations while minimizing system downtime.

Our approach to designing control panels emphasizes modularity and expandability, enabling facilities to accommodate future capacity expansions or process modifications without complete system replacement. This forward-thinking approach protects facility investment while ensuring continued operational effectiveness.

Operational Efficiency Through Intelligent Design

Well-designed control panels enhance operational efficiency through intuitive operator interfaces, automated routine functions, and comprehensive alarm management systems. These features reduce operator workload during normal operations while providing the information and control capabilities necessary for effective response to abnormal conditions.

Aura Engineering’s experience with storage terminal and loading terminal operations enables us to design control panels that streamline routine tasks while maintaining the flexibility required for diverse operational scenarios.

Find a Control Panel Designer at Aura Engineering

Planning a new control panel installation for your storage terminal or loading terminal? Aura Engineering’s expertise in designing control panels for petrochemical facilities ensures your project delivers the safety, reliability, and operational efficiency your facility requires. Contact our seasoned team today to discuss your control panel requirements and discover how our comprehensive design approach can enhance your terminal operations while ensuring regulatory compliance and long-term reliability.